Chope Group provides cement enterprises with professional production and debugging, professional maintenance, technical diagnosis, equipment upgrading, spare parts localization and other technical transformation services.

Undertake large and medium-sized maintenance of cement production line, deal with emergency; make technical transformation of old production line, provide design guidance and personalized equipment manufacturing; increase production and transformation of firing system and grinding system, energy saving and consumption reduction and technical upgrading of equipment for equipment.

Three major system transformation to ensure that cement enterprises achieve production increase, reduce consumption of local equipment technical transformation to solve the following production problems:

Firing system (Preheater)

- System output can not meet the design requirements or limited production space, the system resistance is high;

- C1 outlet exhaust gas temperature is high, cyclone dust collection effect is poor;

- The heat transfer effect of the system is poor and the heat consumption is high.

- There is short circuit and phenomenon of sloughing material;

- The combustion of pulverized coal in the calciner is incomplete, and the temperature of C5 and calciner is inverted.

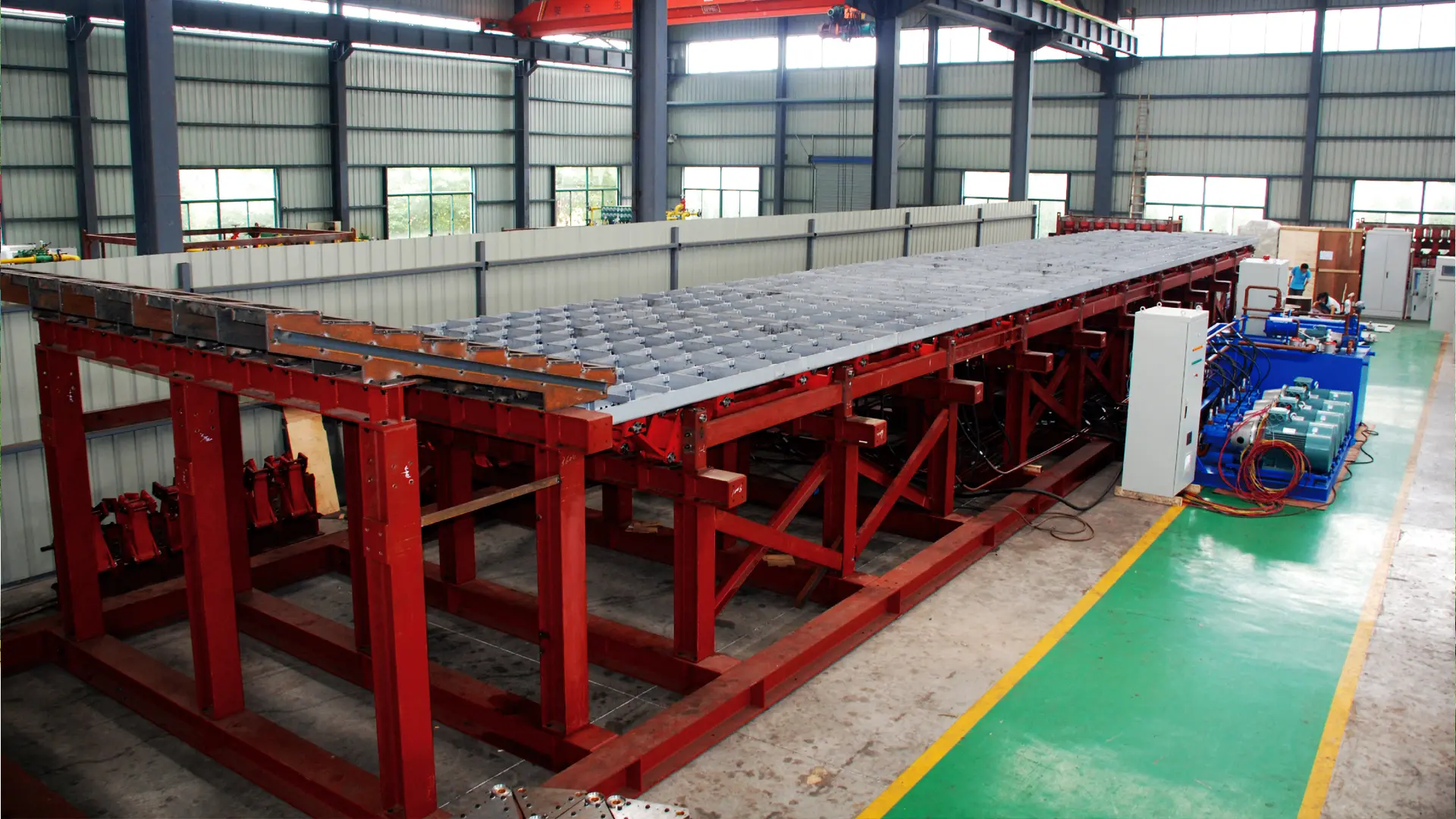

Sintering system(cooling machine)

Taking the core equipment “cooling machine” in the cement production line firing system as an example, the coolers in operation in the current market (including the third generation, fourth generation and fifth generation coolers) often appear in the following situations:

- The phenomenon of “building a snowman”;

- Discharge temperature is too high;

- The transmission device of the third generation cooling machine is often damaged;

- “Red River” phenomenon;

- Clinker crusher often shut down due to anisol;

- The effect of waste heat power generation is not ideal.

- Can not reach the design output, high power consumption.

Grinding system (cement grinding)

- The extrusion effect of roller press is poor

- V-type separator has poor grading effect

- The grinding capacity of the mill is insufficient, the power consumption is large, and the system output is low

- The efficiency of powder sorting is low

- Process design problem

Yunnan toon tree project

Sichuan River oil project

Lafarge Sands Project

Dalian New Tiger project